What We Do?

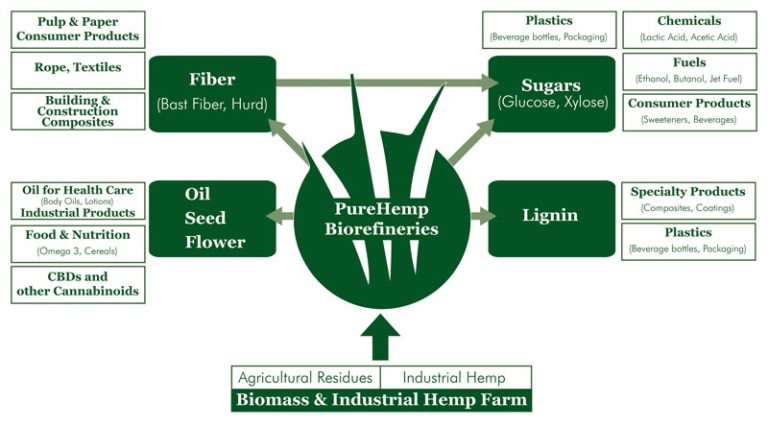

Since 2014, PureHemp has been dedicated to full utilization of different varieties of industrial hemp. We have created three divisions to pursue our whole hemp utilization strategy:

The botanical division, which uses the cannabinoids extracted from hemp flowers, along with other healthy botanical ingredients to manufacture health and beauty products for private label clients and for our Pure Kind Botanicals brand.

The fiber division, employs different stalk processing technologies to manufacture various fiber grades for making pulp & paper products, extruder-based plastics and others. Among these operations, PureHemp is size-reducing whole hemp stalks and decorticating the bast fiber from the inner hurd or wood. The bast fiber can be used to manufacture pulp and the hurd is being milled into different varieties of raw and size-reduced hemp hurd particles.,

The CCR division has a focus on scaling up the CCR technology for biorefining industrial hemp into pulps, lignin and sugars for many industries. PureHemp has secured global technology licensing rights to convert industrial hemp into hemp-based products using the continuous countercurrent reactor (CCR) technology. CCRs rapidly convert non-food biomass such as corn stover, wheat straw, grasses, wood and hemp stalks into biobased products. PureHemp has demonstrated the unique capabilities of the CCR technology that deconstructs hemp into its fundamental components that then become intermediate materials including:

- Pulp, which is one of the products exiting the CCR and is made primarily from the cellulose fraction (about 40%) of the hemp stalks. Pulp is used to produce a wide variety of products including paper products, sugars, alpha cellulose, dissolving pulps, composites and building products.

- Lignin, which makes up about 20% of hemp stalks, is the “glue” that protects and binds the cellulose and hemicellulose fibers. PureHemp is able to fractionate lignin from hemp stalks, which can then be used as a raw material to make many products, including chemicals, binders and plastics.

- Sugars, from the cellulose and hemicellulose fractions of hemp, primarily glucose and cellulose, can be used to produce sweeteners, beverages, chemicals and plastics. PureHemp is currently processing hemp into a growing number of hemp products.

- Cannabinoid-Based Health Products, with the successes of gently converting hemp flowers into full spectrum cannabinoid-rich extracts, PureHemp has created Pure Kind Botanicals™ to provide CBD-rich wellness products. The Fort Lupton, CO-based PureHemp staff is currently converting hemp into the following products:

100% hemp sugars successfully used to produce hemp beer and organic ethanol

Hemp pulp for paper, packaging, posters and many more paper-based products.

Hemp xylose has been upgraded to organic xylitol, the healthiest sugar known

Lignin (about 20% of the hemp stalks) can be converted into plastics, resins and starting materials to produce a wide array of consumer and industrial products.

PureHemp is on the ground floor of the renewed U.S. hemp-refining industry. PureHemp is an important link in the emerging value chain from farmer to consumers, and also by:

- Partnering with other hemp-inspired technology and development companies

- Providing fiber products and equipment to the hemp community

- Providing technology licensing packages to project developers and entrepreneurs

- Pushing the boundaries of what can be produced from the versatile hemp plant